Unveiling the Craftsmanship Behind Custom Wine Cabinets: From Design to Delivery

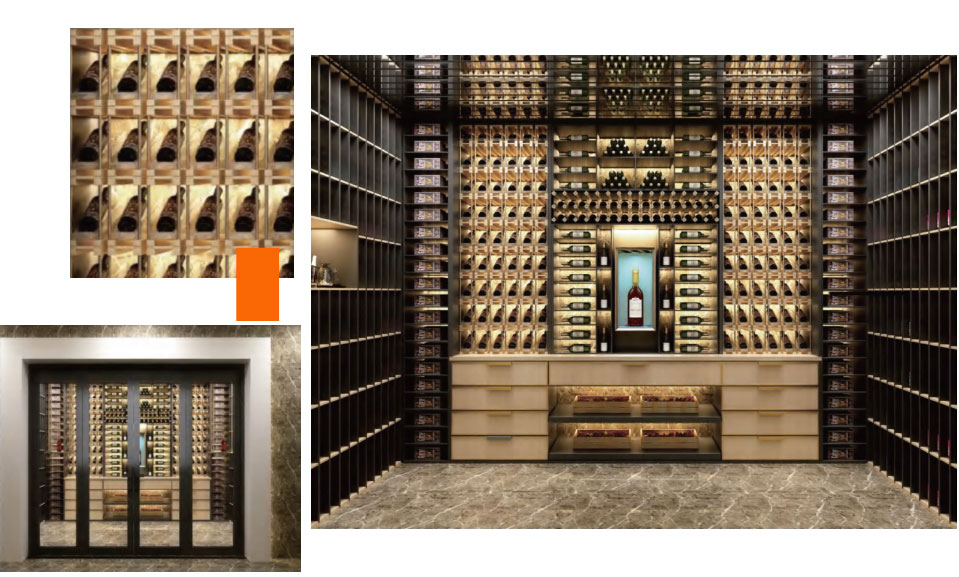

In the world of fine wine, storage is more than just functionality—it's a statement of lifestyle, sophistication, and taste. For serious wine enthusiasts and luxury homeowners alike, a custom wine cabinet is the ideal way to showcase and preserve a wine collection while harmonizing with the interior space. But what exactly goes into the creation of a tailor-made wine cabinet?

Behind the elegant glass doors and polished finishes lies a meticulous, multi-stage process that involves technical expertise, artisanal craftsmanship, and a deep understanding of wine storage principles.

1. Client Consultation and Needs Assessment

The journey begins with an in-depth consultation between the client and the design team. This step is crucial for understanding the customer’s vision, space limitations, storage requirements, and aesthetic preferences.

Key topics include:

Wine collection size and types (reds, whites, sparkling, aged)

Desired storage capacity (bottle count and layout)

Location (kitchen, living room, wine cellar, restaurant)

Climate control needs (temperature and humidity)

Preferred materials (wood, stainless steel, glass, or a mix)

Lighting, shelving styles, and door options

Budget and timeline

Based on this discussion, a preliminary concept is developed that balances both form and function.

2. Conceptual Design and 3D Rendering

Once the requirements are gathered, professional designers create CAD drawings and 3D visualizations of the wine cabinet. These digital models allow the client to preview the structure, color schemes, shelving layout, and finishes before production begins.

This stage allows for easy adjustments to:

Dimensions and bottle arrangement

Integration with surrounding furniture or architecture

Selection of finishing details like handles, legs, and lighting

Advanced rendering tools can simulate how the cabinet will look in the actual space, enabling the client to make confident design choices.

3. Material Selection and Engineering Planning

After the design is finalized, the next step involves selecting premium materials and components. This is where the true quality of a custom wine cabinet begins to take shape.

Typical materials include:

Solid woods (oak, walnut, mahogany) for elegance and durability

Stainless steel for a modern look and long-term performance

Tempered glass for doors or shelving with safety and style

Aluminum or carbon steel for structural support

Insulation materials to maintain internal temperature and humidity

Low-E glass and double-pane doors for climate control

An engineering team then prepares technical plans for the internal cooling system, wiring for LED lighting, and air circulation layout—especially if the cabinet includes built-in climate control.

4. Precision Manufacturing and Craftsmanship

With drawings and materials approved, the manufacturing process begins in the workshop. This stage combines modern machinery with artisan handwork to ensure both accuracy and detail.

Key steps include:

Cutting and machining of panels and frames with CNC precision

Carpentry and assembly for wooden elements, including jointing, sanding, and veneering

Welding and polishing for metal frames and stainless steel parts

Tempered glass processing, including cutting, edging, and treating

Integration of cooling units, compressors, and ventilation systems for refrigerated models

Each component is inspected for accuracy, finish quality, and structural integrity before being assembled.

5. Finishing Touches and Quality Control

The finishing process is where the wine cabinet comes to life. Skilled artisans apply:

Wood stains or lacquers, enhancing the grain while protecting the surface

Polishing and brushing for metal components to achieve the desired shine or texture

Etching or frosting for decorative glass effects

Soft-close hardware and premium hinges for functionality

Once assembled, the cabinet undergoes rigorous quality control checks, including:

Door alignment and seal testing

Cooling system calibration and noise level tests

LED lighting function tests

Final inspection of all surfaces and fittings

This ensures the final product meets both the client’s expectations and high manufacturing standards.

6. Delivery, Installation, and After-Sales Support

Once quality testing is complete, the wine cabinet is carefully packaged for safe delivery. Some high-end manufacturers provide white-glove installation services, ensuring the cabinet is correctly positioned, leveled, and plugged in by professionals.

During installation, technicians may:

Configure temperature and humidity settings

Provide operational training to the client

Adjust shelving based on bottle types (Bordeaux, Burgundy, Champagne)

Reputable manufacturers also offer after-sales support, including:

Maintenance tips

Warranty services

Replacement parts

Long-term support for climate control systems

7. Personalization That Tells a Story

What truly sets custom wine cabinets apart is the ability to reflect the owner's personality and story. Whether it’s a carved wood crest, integrated wine-tasting table, color-coordinated LED lighting, or special compartments for decanters and glasses—every detail can be tailored.

Some luxury cabinets even include:

Smart temperature control with mobile apps

Security locks for rare vintages

Built-in humidifiers and UV filters

Hidden drawers or dual-zone cooling systems

Where Craft Meets Culture

The creation of a custom wine cabinet is far more than just manufacturing—it is a collaborative, artistic process that bridges lifestyle, architecture, and the fine tradition of wine appreciation. From the initial sketch to the final polish, each stage is guided by attention to detail, technical precision, and a passion for timeless craftsmanship.

Whether for a private home, a boutique hotel, or an upscale restaurant, a well-designed custom wine cabinet is a lasting investment—one that protects treasured vintages while enhancing the atmosphere and aesthetic of any space.

Hot News

Best Stainless Steel Wine Cabinet for Home

Stainless Steel Cabinets vs. Wood Cabinets: Which is the Better Choice for Your Kitchen?

Minimalist Kitchen Design: How Stainless Steel Cabinets Fit the Trend

Creative Uses of Stainless Steel Wall Niches in Contemporary Interiors

Stainless Steel vs. Wooden Wine Cabinets: Pros & Cons

Glass Door vs. Solid Door Stainless Steel Wine Cabinets: What’s Best?

High-End vs. Budget-Friendly Stainless Steel Wine Cabinets: A Buyer’s Guide