304 vs 316 Stainless Steel Cabinets: Corrosion Resistance Comparison and Suitable Applications

Stainless steel is a popular choice for cabinets due to its durability, strength, and resistance to corrosion. Among the various stainless steel grades, 304 and 316 are the most commonly used for cabinetry, particularly in residential, commercial, and industrial settings. While both offer excellent resistance to rust and staining, their corrosion resistance levels differ due to their chemical composition.

Chemical Composition and Corrosion Resistance

The key difference between 304 and 316 stainless steel lies in their composition. Both are austenitic stainless steels, primarily made of iron, chromium, and nickel, but 316 contains an additional element—molybdenum.

304 Stainless Steel: Composed of approximately 18-20% chromium and 8-10.5% nickel, 304 stainless steel provides good corrosion resistance against most oxidizing acids. However, it is vulnerable to chloride exposure, which can cause pitting and crevice corrosion over time.

316 Stainless Steel: Contains 16-18% chromium, 10-14% nickel, and an additional 2-3% molybdenum. The presence of molybdenum significantly enhances its resistance to chlorides, making it more suitable for harsh environments with high exposure to salt, chemicals, and acids.

Due to the inclusion of molybdenum, 316 stainless steel exhibits superior resistance to:

Saltwater corrosion, making it ideal for marine environments.

Industrial chemicals, including acids and alkalis.

Pitting and crevice corrosion, especially in humid or chloride-rich areas.

Application Scenarios

When choosing between 304 and 316 stainless steel for cabinetry, the intended environment plays a crucial role in the decision-making process. Below are the most common applications for each grade:

304 Stainless Steel Cabinets

Indoor Kitchens and Residential Use: 304 stainless steel is widely used for kitchen cabinets and appliances due to its strength, ease of cleaning, and aesthetic appeal.

Commercial Food Preparation Areas: Restaurants, cafeterias, and food processing facilities commonly use 304 stainless steel cabinets, as they resist food acids and maintain hygiene standards.

Office and Garage Storage: Due to its durability and resistance to moderate environmental exposure, 304 stainless steel is an excellent choice for office storage and garage cabinetry.

Medical and Laboratory Equipment: In controlled environments where exposure to aggressive chemicals is minimal, 304 stainless steel provides sufficient protection against corrosion.

316 Stainless Steel Cabinets

Marine and Coastal Areas: Given its superior resistance to saltwater corrosion, 316 stainless steel is the preferred choice for cabinetry on boats, ships, and coastal properties.

Chemical and Pharmaceutical Industries: Facilities that handle strong acids, alkalis, and other corrosive chemicals benefit from 316 stainless steel cabinets to ensure longevity and safety.

Outdoor Kitchens and Grills: For outdoor cooking spaces where cabinets are exposed to rain, humidity, and salt air, 316 stainless steel is recommended for its resistance to rust and corrosion.

Hospitals and Cleanrooms: Environments requiring high sterility levels, such as hospitals and pharmaceutical production areas, often opt for 316 stainless steel due to its enhanced chemical resistance.

Cost Considerations

Another significant factor when choosing between 304 and 316 stainless steel cabinets is cost. Due to its additional molybdenum content, 316 stainless steel is typically 25-30% more expensive than 304 stainless steel. While this extra cost may not be justified for standard indoor applications, it is a worthwhile investment for environments with high exposure to corrosive elements.

Maintenance and Longevity

Both 304 and 316 stainless steel cabinets require minimal maintenance, but their longevity depends on the environment and proper care:

Regular cleaning with mild soap and water helps maintain their finish.

Avoiding prolonged exposure to harsh chemicals can prevent potential degradation.

In chloride-rich environments, 316 stainless steel requires less frequent maintenance than 304, making it more cost-effective in the long run.

Choosing between 304 and 316 stainless steel cabinets depends on the application’s environmental conditions. While 304 stainless steel offers excellent durability and corrosion resistance for most indoor applications, 316 stainless steel is the superior choice for outdoor, marine, or industrial environments where exposure to salt and chemicals is high. Understanding these differences ensures the right selection for long-lasting, high-quality stainless steel cabinetry.

Hot News

Best Outdoor Stainless Steel Cabinets: Features, Prices, and Buying Tips

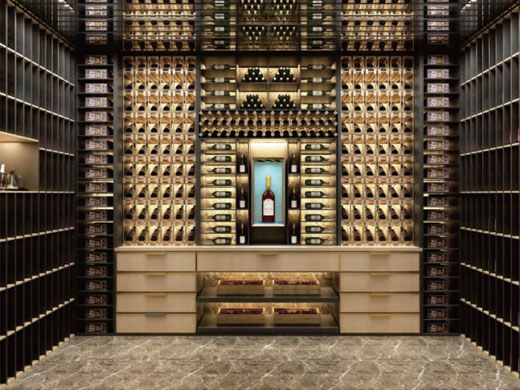

Built-in vs. Freestanding Stainless Steel Wine Cabinets

Stainless Steel Wine Cabinet: Ultimate Guide for Modern Wine Storage

How to Choose the Right Stainless Steel Wine Cabinet: A Complete Buyer’s Guide

What Size Stainless Steel Wine Cabinet Do You Need?

Single-Zone vs. Dual-Zone Stainless Steel Wine Cabinets: Which One Should You Choose?

Best Commercial Stainless Steel Wine Cabinets for Bars & Restaurants